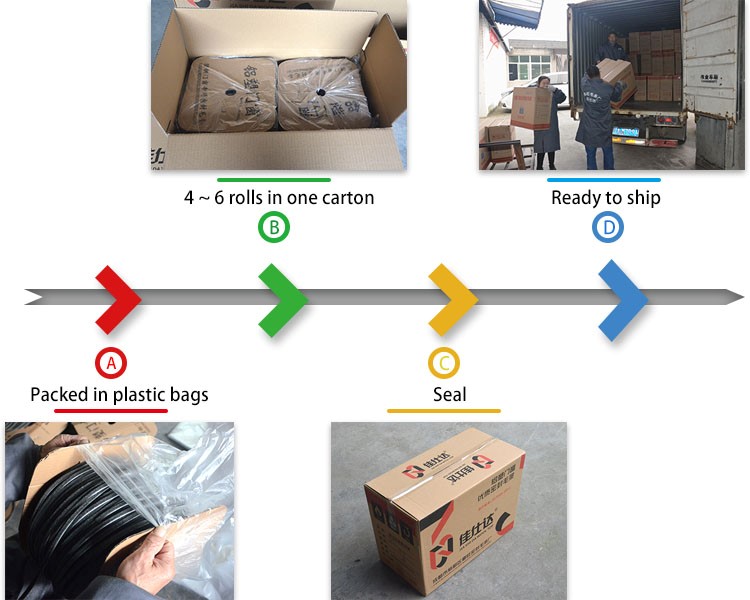

Packing by paper carton , roller packing by plastic bag, then put in carton 4 rolls/carton, 250 meters/rollBrand: JYD Craft: 3P2L/ 3P3L Base width: 6.8mm Pile height: 8/10mm(include base height) Base height: 0.6~0.8mm

Packing by paper carton , roller packing by plastic bag, then put in carton 4 rolls/carton, 250 meters/rollBrand: JYD Craft: 3P2L/ 3P3L Base width: 6.8mm Pile height: 8/10mm(include base height) Base height: 0.6~0.8mm In the wool spinning process, wool fibers must be processed into tops before they can be spun into wool. Door and window sealing strips are made of BCF FDY and pp through a special process. Guaranteed 300 fluff per square centimeter, good sealing effect. After the washed wool is combed into sliver, it goes through the preparation and finishing processes before and after combing to make a combed top, which is then spun into yarn for worsted wool spinning. The process includes carding, slitting, combing, slitting and rewashing, slitting, roving, spinning and other processes.

The sealing wool of doors and windows plays a key role in wooden doors, anti-theft doors, sliding doors, various aluminum-plastic doors and windows and other doors and windows. The most obvious is shockproof. After it is installed on the door stop line, it reduces (or even disappears) the collision sound when closing the door (window), protects the edge of the door leaf, prolongs the service life of the door and reduces the noise. The second is sealing, shock absorption and isolation of indoor and outdoor air, which effectively plays a role in heat preservation and energy saving, and will prevent mosquitoes and other small insects from drilling indoors.

Q: Are you a trading company or manufacturer? A: We are a factory. Q: How long is your delivery time? A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity. Q: Do you provide samples? is it free or extra ? A: Yes, it is free. Q: How can you guarantee the quality? A:Experienced team of engineers and strict quality control. If you meet with quality problem, we promise to replace goods or return your funds. Products are approved by SGS,ISO9001. Q: I don’t find I want, can you OEM to me? What about minimum order quantity? A:Yes, we are a professional OEM manufacturer more than 20 years’ experience, we have a large supper ability, but we never refuse to small orders, the MOQ can be 5000 meters.

Q: Are you a trading company or manufacturer? A: We are a factory. Q: How long is your delivery time? A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity. Q: Do you provide samples? is it free or extra ? A: Yes, it is free. Q: How can you guarantee the quality? A:Experienced team of engineers and strict quality control. If you meet with quality problem, we promise to replace goods or return your funds. Products are approved by SGS,ISO9001. Q: I don’t find I want, can you OEM to me? What about minimum order quantity? A:Yes, we are a professional OEM manufacturer more than 20 years’ experience, we have a large supper ability, but we never refuse to small orders, the MOQ can be 5000 meters.